Photogrammetry in combination with drones is an interesting measurement technique. Just a short time ago, Argus Vision successfully proved so with the Quartier Bleu case, a brand-new living and shopping complex in Hasselt. The rough concrete core of the building was mapped by Argus Vision and surveyor Divatec. The WTCB compared the results of laser scanning to those of Argus Vision’s technology.

The outcome? Both techniques deliver similar results. More even, they are totally compatible, with one technique balancing out the ‘grey zones’ of the other, hence why in some cases using them in tandem is advisable.

New measurements required

Quartier Bleu will no doubt become one of Hasselt’s new hotspots. Experience is what it’s all about in this initiative by developers Chateaux Real Estate and Matexi, a mix of apartments, fancy restaurants and trendy shops. This atmospheric new quarter by the canal consists of seven volumes. The concrete structure is finished with different materials, for example natural stone.

“This cladding material comes from Brazil”, says Jonas Van de Winkel, co-owner of Argus Vision. “To save time, the stone could be cut to size in Brazil as well. In theory this sure was an interesting option, however, in practice such exercise proved to be a lot more difficult. Once the concrete core had been constructed, inevitably discrepancies showed up. So before starting cutting up the stone slabs, everything had to be measured again.”

Photogrammetry for increased accuracy

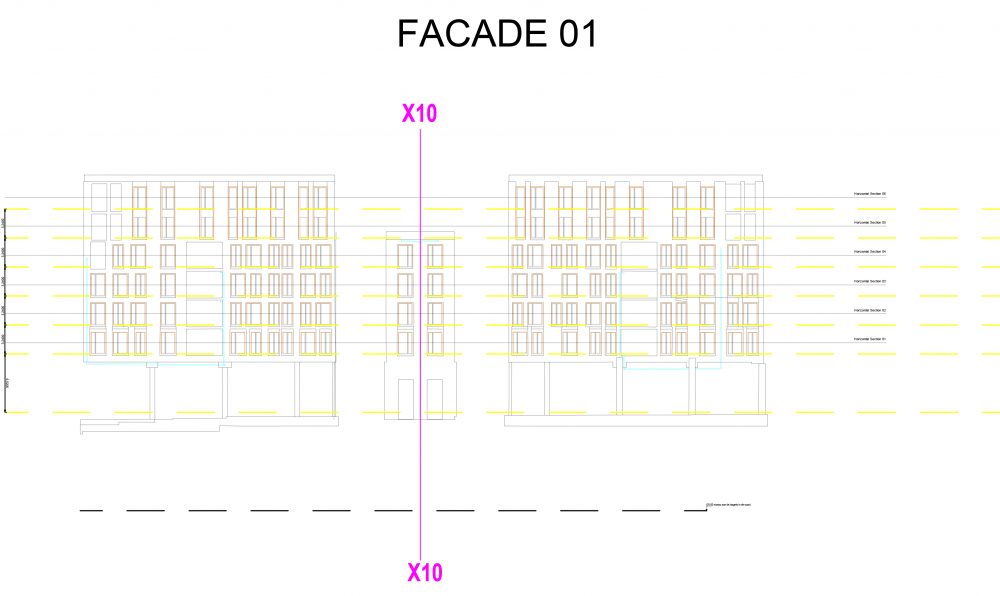

In order not to lose time, surveying company Divatec had to act quickly. However, this project was no walk in the park. Especially the location proved to be quite the challenge. “The actual measuring work had to take place in a very narrow street”, explains Dieter Vandepoel, surveyor-expert. “Far from easy, since some volumes consist of 7 building layers. It immediately became clear a traditional way of measuring would not deliver the required level of accuracy, because laser scanners need a sufficiently wide angle and a short measuring distance. Normally, we would solve this by measuring at a higher position, for instance from flats across the road. In the case of Quartier Bleu, this was not always possible. So we called in Argus Vision, who combine photogrammetry and drones, which enabled us to map all volumes, despite any obstacle.”

What is photogrammetry?

Photogrammetry implies digital image capturing, all with a certain overlap. “Our standard is that each point has to return in at least nine images”, details Seppe Koop, co-owner of Argus Vision. “Using special software, we compare these points with the GPS position of the camera. These results are used to create a point cloud that is checked against the control points of the surveyor. We placed 40 points per 100 running metre of façade. Our photos come in an extremely high resolution: 1 mm/pixel, which gives an accuracy of approximately 0.5 cm on the XYZ axis, a comparable level to that of laser scanning.”

Scientific comparison

Initially, Divatec only wanted to use photogrammetry to compensate the shadow areas that are typical for laser scanning. The Belgian Building Research Institute (BBRI / WTCB) however saw a great opportunity to compare both techniques. “That is why we made a 3D scan of the entire building”, says Jonas Van de Winkel.

“Divatec and ourselves processed our data into several views and intersections of each floor. Obviously, the surveyor used part of the photogrammetry data to compensate the blind spots of laser scanning, whereas we bridged the gap with the measuring points Divatec had defined. This proves both techniques are compatible. Moreover, analysis by the WTCB showed that for concrete surfaces results came out with equal quality, with a maximum deviation of no more than 5 mm! But the measurements of aluminium joinery were less positive, since the lack of texture made it hard to detect reference points using photogrammetry. The model was quite distorted in these cases, with deviations up to about 5 cm. Conclusion: it is best to combine laser scanning with our technology, especially for complex and high buildings. They are perfectly compatible and fill in the grey zones, surveyors no longer need to take the risk of neck breaking climbs and the measurement process is complete a lot quicker.”

Proof of efficiency

The results caught the eye of not just Divatec and Argus Vision. The WTCB also was very happy with the outcome. Prof. Dr. Ir.-Arch. Michael de Bouw, responsible of the ‘Labo Renovatie en Erfgoed’: “We need to keep up-to-date on new technology and make an objective assessment. Photogrammetry combined with drones is a promising innovation. Many of our members are interested in applying this technique but still have questions on its efficiency and precision levels. This case has established both of these parameters are more than acceptable, in black and white. At the same time, this was the perfect opportunity to compare the three main software packages; one of the main topics our members regularly send us questions about.”

Software analysis

The WTCB imported Argus Vision’s point cloud in three different software packages. “We indeed saw different results”, continues Michael de Bouw. “A solid visualisation for instance does not always guarantee the highest level of accuracy. And a high-density point cloud does not necessarily offer more precision than a less dense cloud. The three software packages did have one thing in common: corners of aluminium joinery were difficult to map. In the end, only one program was able to minimise that deviation to approximately 1 cm. Anyway, this has been a very interesting exercise from which we drew many a lesson. Still, we need a more structured and in-depth study, including in-situ tests with companies, as to guarantee the quality and possibilities of such 3D measurement techniques in the future.”

New application found

To Argus Vision, the Quartier Bleu case gave rise to new commercial options. Seppe Koop explains: “Photogrammetry with drones is ideal for use in an urban context, for example with sixties buildings that are being totally stripped. Before the rebuild can start, it is pivotal the concrete core is measured up meticulously. Quartier Bleu proved this can easily be done with photogrammetry, in a very short period of time. And then there is the benefit of the drones being able to reach the more difficult zones. That’s how you know Argus Vision offers the ideal solution.”