Taking stock of a large amount of different materials stored in an outside space? That can be done fast, safely and accurately thanks to drones in combination with photogrammetry, as proven by Argus Vision twice already in projects commissioned by APK Group. On request of surveying company Divatec, building debris and respective recyclable materials have been listed for five sites. For each terrain the drone specialist only needed two hours to draw up a ready-to-use report; with a level of detail that could never be equalled using manual measurement techniques.

APK Group transforms its building debris into new raw materials at its sites in Langemark, Verrebroek, Overpelt, Maasmechelen and Genk. In order for their financial reporting to be correct, a stock-take of all materials is required each year: a project that is executed by surveyor Divatec. “Such measurements are pretty challenging”, states surveying expert Dieter Vandepoel. “This stock-take literally entails ‘mountains’ of raw materials and recycled products, up to 6 meters high. With the conventional technique using a GNSS station, we would have to climb these mountains; which not only takes up loads of time but also is pretty risky. To keep costs down, we need to minimise the number of measurement points, which means we can only provide a close estimation of the actual volumes. This is why since a couple of years we collaborate with Argus Vision for this kind of projects. The way they combine photogrammetry and drones means we are no longer limited by the disadvantages of traditional measurement techniques.”

Accurate and extremely fast

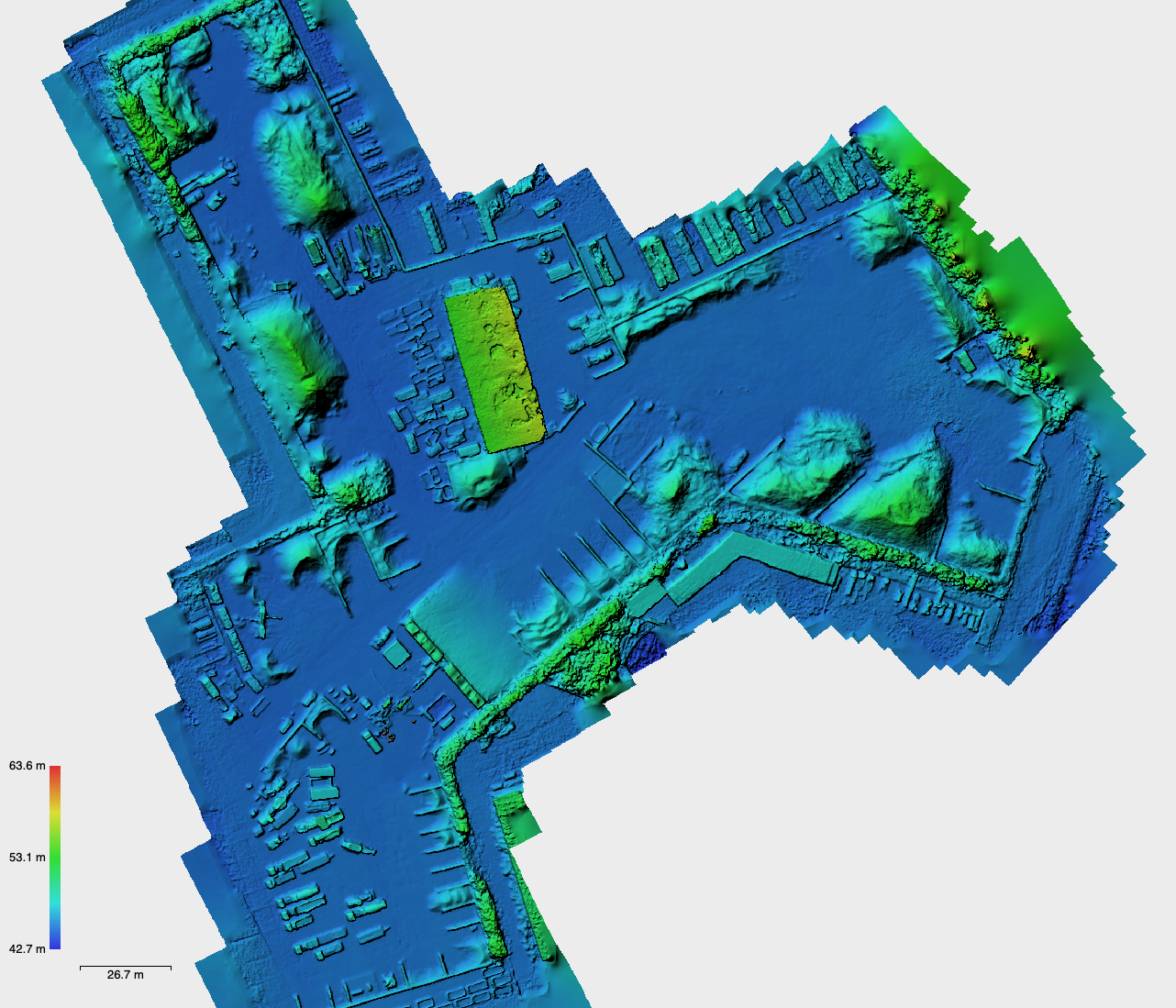

In case of the APK Group project, Divatec and Argus Vision even work together physically. “For an optimal measurement result, Divatec defined 15 to 25 control points manually”, explains Jonas Van de Winkel, co-owner of Argus Vision. “These are the reference to refine our rough point cloud. Obviously, we want to work as accurately as possible from the start; in this case for instance we used a camera with a corrected lens to avoid measurement deviations. We also used an 85% overlap when taking photos, for the front as well as the sides. This means 600 to 800 images per site in practice, which suffices to construct a 3D model on a 3 and 6 cm accuracy scale on the XY and Z axis respectively. Since our method delivers a significantly higher number of measurement points than when a GNSS station would be used ‒ 1000 per sqm versus 1 per 5 sqm ‒ we are able to write up a very precise inventory report. Even in no time at all: though the sites are located all over Belgium, we just needed a day and a half to map all five of them.”

From image to template

Straight after measurement was done, Argus Vision got started. “The images are processed in a customised way, to suit the purposes”, continues Dieter Vandepoel of Divatec. “Without any doubt, this is the main benefit this drone specialist offers. Only few have the know-how and software to process all captured information fast and correctly into an instrument that is immediately ready to hand over to the client.” “In this instance, we started with a rough point cloud of the images”, details Seppe Koop, co-owner of Argus Vision. “This cloud subsequently was matched with the control points determined by the surveyor. Next, we filtered all vegetation, machines and buildings out of the point cloud, to end up with a Digital Elevation Model ready to be imported in the Virtual Surveyor software. That enabled us to determine the contours of the ‘boxes’ of material or raw material, which also serves as the benchmark for the volume that needs to be measured.” “In fact we created kind of a template Virtual Surveyor can use to automatically calculate the volume”, specifies Jonas Van de Winkel. “For the next stock-take, we can skip this step, at least if the lay-out of the site has remained unchanged. What’s more, this approach allows to create a graph that shows the trend of each volume over the years.”

Inventory from A to Z

The last step consisted of linking the images to a list of all the materials. “This list was given to us by APK Group”, says Seppe Koop. “Part of it was digital, other parts were sketches. Some raw materials were missing, but we still managed to draw up a complete report. Meanwhile we have gained plenty of expertise to correctly interpret high resolution drone images. With some additional research, we were able to identify all materials.” “We linked these data with our analysis, to create a table of references and volume per material. We also drew up a map with the contours of the different materials”, adds Jonas Van de Winkel. “Per site, Argus Vision needed about 2 hours to complete all measurements. Processing these data took up about 1.5 hours each”, points out Dieter Vandepoel. “Thanks to the use of drones, time on site was cut by at least half and we were able to combine several sites. That way, we could offer our client a very interesting rate, for a stock-take that is extremely detailed and accurate. So it comes as no surprise this year again APK Group opted for the drones-photogrammetry combination.”