A tragic accident forced International Car Operators to inspect the lighting situation all over their site. In order to avoid any additional incidents, the cargo handling and storage company really needed a quick result. A traditional approach wasn’t an option, since that would take weeks.

Hence they approached Argus Vision, which turned out to be a brilliant move. In just a handful of hours the drone specialist collected enough data to create a detailed lighting map that ICO could get to work with immediately.

375 hectares with vehicles

Japanese company ICO is one of world’s most important handling and storage companies of cars, constructions materials and heavy lifts. ICO is a 100% subsidiary of Nippon Yusen Kaisha, handling more than 2.5 million cars on Belgian soil each year, via the ports of Antwerp and Zeebrugge. This means ICO is able to offer a solid ‘hub and spoke’ concept to the entire automotive industry in Europe.

“In Antwerp, our terminal spans 125 hectares”, explains Jan Werbrouck.

“Zeebrugge is even more important, with three sites spread over more than 250 hectares.”

Lighting map urgently required

Each site is a busy hive, 24 hours a day. In order to work efficiently at night time as well, ICO invested heavily in the lighting of their terminals. But still, the question rose whether this lighting would be sufficient; even more so after someone tragically drove a car into the water. “The cause of this unfortunate accident wasn’t immediately clear”, states Jan Werbrouck.

“An important train of thinking in the investigation was that the level of lighting just wasn’t adequate. For us, it then became crucial to prove the opposite or to take any action required, should this effectively have been the cause. Of course, under no circumstances did we want to have to confront such accident again.”

Drones as a fast alternative

Given the size of the ICO sites drawing up a lighting map would take weeks, if the traditional approach was used. Jan Werbrouck: “Fortunately, we have been collaborating with Argus Vision for a while now. This drone specialist already succeeded to chase seagulls off our site. Their penchant for innovation triggered us to reflect… Could drones be used to measure the light intensity at our sites? When we actually asked that question, the answer came back positive. That is the story how we in no more than 24 hours were holding a very detailed lighting map in our hands.”

The same technique as photogrammetry

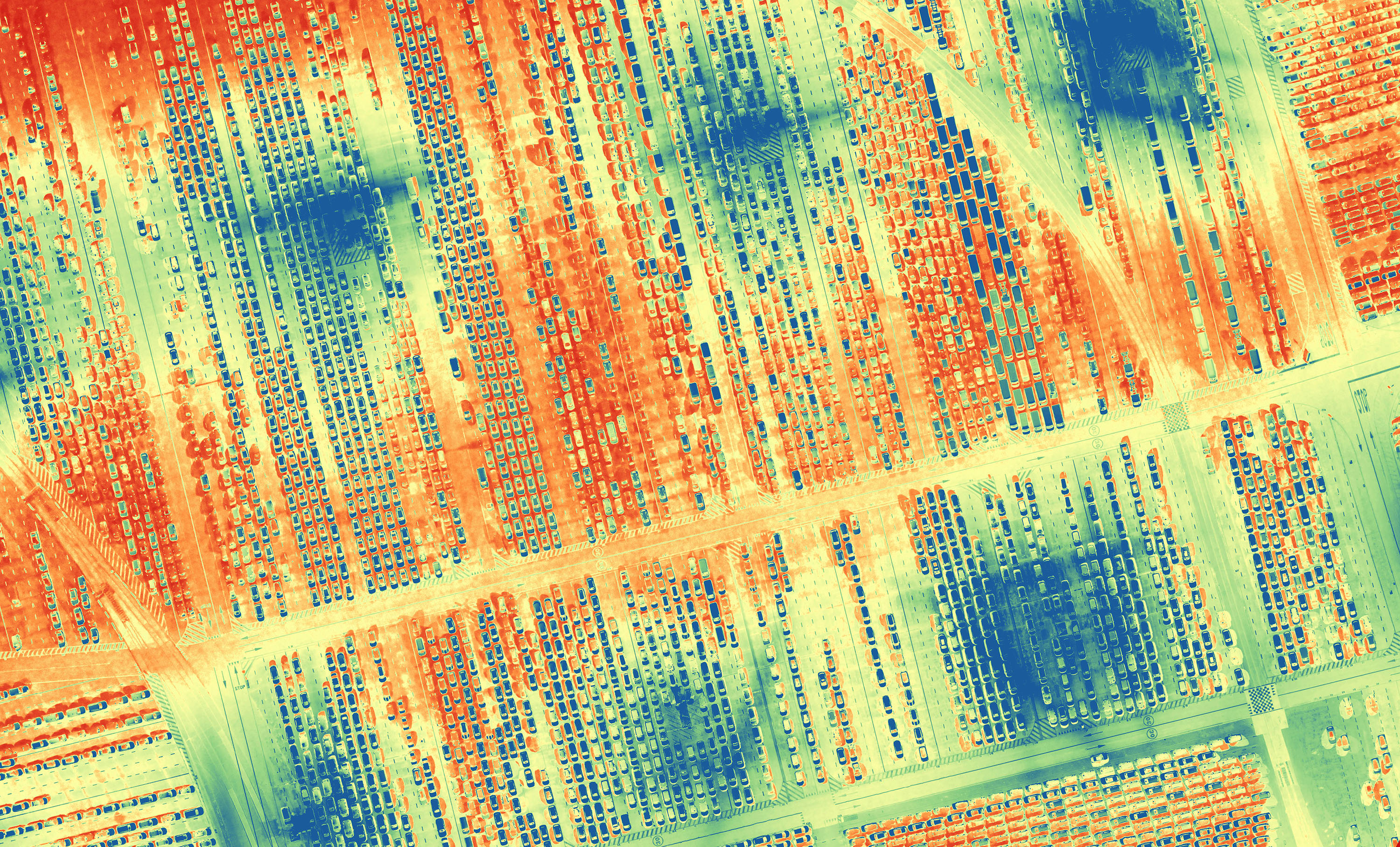

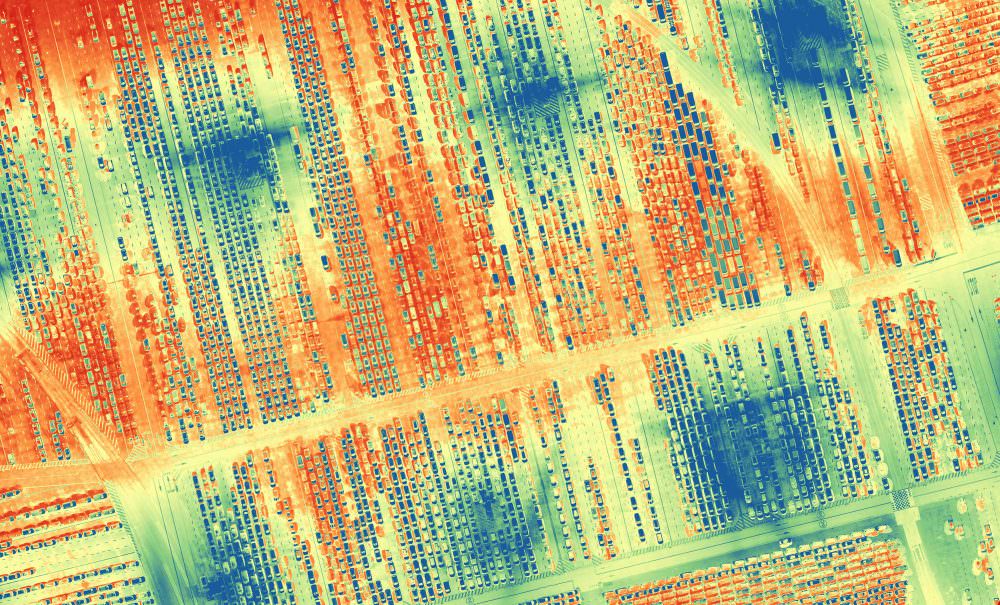

Argus Vision went to Zeebrugge to map the site using drones, an RGB camera and a lux meter. “We applied the same technique we would do using photogrammetry”, points out co-owner Jonas Van de Winkel. “Since the client didn’t need a 3D model, we just executed a ‘nadir flight’, which means the camera takes photos at a 90° angle. By ensuring a sufficient amount of overlap at the front and sides, we attained an image that was accurate enough. After 6 hours of flying, we had shot a sufficient number of images to create a ‘categorised’ lighting map.”

Speed at a great price

Concretely, Argus Vision remodelled the images into a normal ortho map. “We manually measured the artificial light intensity at 30 benchmark points”, explains Seppe Koop. “We then split the registered lux values in six categories, each with their own dedicated colour. These results were linked to the ortho map, after which specific software divided the map in different categories based on pixel values. The end result is a coloured map that clearly visualises the intensity of the artificial light all over the site. Each pixel can be identified via an XYZ coordinate, which enables ICO to exactly localise any problem areas.”

“In no time at all, Argus Vision provided us with an efficient tool that immediately gave us the definite answer regarding lighting intensity on our site”, concludes Jan Werbrouck. “Argus Vision’s technology proves to be very efficient to capture the entirety of the situation. From now on, we know the exact lighting level at any location of our terminal. This has been a very successful project at just a fraction of the cost of manual lux measurements.”